-

Working pressure: 7~13bar 100~190psig Air delivery: 2.5~102m3/min 88~3600cfm Working power: 22~560kw 30~750hpdirect driven

-

Working pressure: 7~13bar 100~190psig Air delivery: 0.7~3.8m3/min 25~134cfm Working power: 7.5~22kw 10~30hpcombined

-

Working pressure: 6.5~13bar 95~190psig Air delivery: 0.5~102.0m3/min 17.7~3600cfm Working power: 5.5~560kw 7.5~750hp Frequency range: 40%~100%VSD

-

Working pressure: 6.5~13bar 95~190psig Air delivery: 0.5~102.0m3/min 17.7~3600cfm Working power: 5.5~560kw 7.5~750hp Frequency range: 40%~100%PM

-

Working pressure: 4.0~13bar 58~189psig Air delivery: 9.5~61.9m3/min 335.5~2189cfm Working power: 55~315kw 75~420hptwo-stage

-

Working pressure: 7~35bar 100~508psig Air delivery: 5.0~37.0m3/min 177~1310cfm Working power: 37~447kw 50~600hpportable

How to Manage the Compressor Room

Air compressor, as a general equipment in manufacturing industry, has become an important form of energy generation, providing the front end of production with a steady stream of pure oil-free air. Once the air compressor unit equipment stops, it will affect the normal production operation, so it is crucial to ensure the safe operation of air compressor.

To ensure safe operation of the air compressor room needs to do a good job of management, including air compressor use management air compressor maintenance management air compressor parts procurement management in its maintenance is also a lot of details do a good job of maintenance, in order to extend the service life of air compressor.

How to manage the compressor room, Elang put together a secret book for you:

Location

1. Should choose a broad, daylighting is good places for air compressor operation of the maintenance and repair the lighting planning, in the place of installation space and selected the most workers often ignored by the compressor after purchase just looking for a position, piping immediately after use, no advance planning but so hasty results, was formed in the future to a bad compressor maintenance difficulties and compressed air to the reasons such as poor quality so choose good installation site is a prerequisite for the correct use of air compressor system.

2. If the compressor is installed in the upstairs, must be done anti-vibration treatment, in order to prevent the vibration to the downstairs, or resonance, the compressor and the building itself have safety hazards.

3. The installation foundation of the air compressor shall be built on the hard ground. Before installation, the foundation plane shall be leveled to avoid noise caused by vibration of the compressor. The vibration produced by the screw air compressor is small. If possible, it is better to lay 5-10mm cushion at the bottom of the unit.

Management

1. Accompanied by and managed by special personnel, the air compressor room and personnel management log were established, and the operating time and running state of the operator were recorded by switching the machine on and off every day, which provided important information for the management of the air compressor and the late maintenance of the running track.

2. Operators should read the operation manual before the operation and maintenance of the air compressor, when there is a change (including the operation state), must immediately notify the equipment after-sales service personnel should pay attention to regular maintenance and maintenance of the air compressor parts, so that the machine and equipment in the best running state.

3. Daily safety: Pay attention to keep the ground clean, no accumulation of debris, especially inflammable and explosive materials, and should be equipped with fire extinguishers and other facilities to ensure the safety of the machine room.

Environment

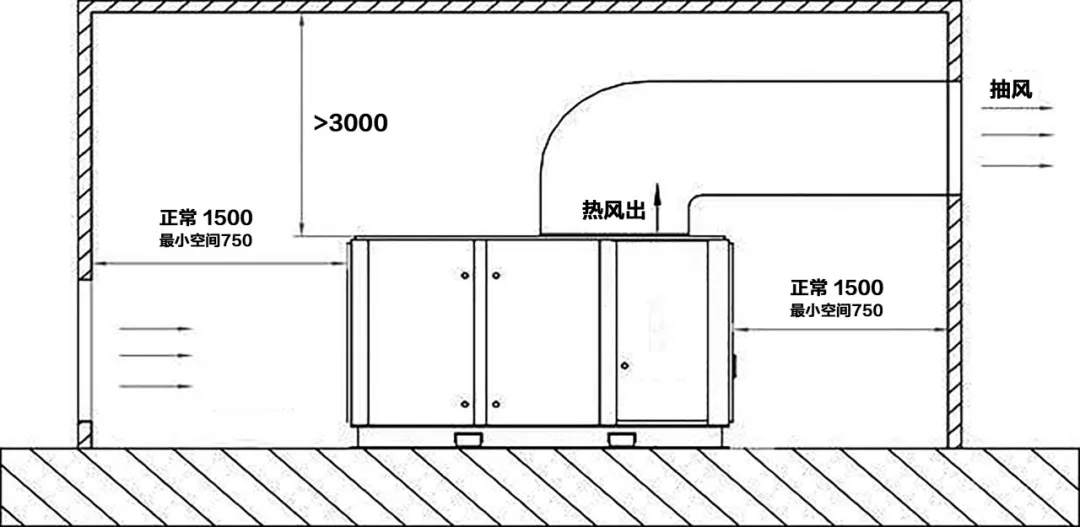

1. The air compressor should not be placed close to the wall. Elang suggests that you keep a distance of 1.5 meters between the air compressor and the wall under normal conditions. If the space is limited, a distance of at least 75cm should be set aside to ensure a certain amount of space for ventilation and maintenance, which is also conducive to the maintenance and maintenance of the air compressor

2. The air compressor room should maintain a certain ambient temperature, should not be higher than 38, should not be lower than 0 note that the air pressure room temperature as far as possible to control in a lower state, air compressor absorption of higher temperature air will reduce the exhaust volume.

3.Room where the place should be kept dry and ventilated condition is good, the air is fresh, and try to avoid more dust oil wet environment, to reduce the damage to compressor, extending its service life, cannot make the air compressor suction has more molecules and contain explosive or corrosive air paint chemical instability or steam and other gases, so as not to endanger the air compressor unit staff or due to the use of rapid damage such as factory environment is poorer, dust, must be mounted to the front in front of the air compressor suction mouth filtering equipment.

4.The pressure pipe in the air pressure room is strictly forbidden to bump against, and it is strictly forbidden to disassemble under the condition of live belt pressure.

5.Even in a reasonable use environment, the compressed air will still contain a large amount of water and a small amount of oil, which will reduce the production efficiency and product quality of the factory. Moreover, the untreated air cannot be directly used for breathing or food contact, so the corresponding air post-treatment equipment must be installed.

About Elang:

Product Recommendation:

Company News:

-

Wating to meet you in HANNOVER

Date: Apr 4, 2019

-

Why choose us

Date: Apr 19, 2019

-

Global Recruitment Agency

Date: Jul 19, 2019

-

PTC Asia Invitation

Date: Jul 25, 2019

-

How to Choose the Location of the Air Compressor Room?

Date: Aug 19, 2019

-

How to Arrange an Air Compressor Room?

Date: Sep 4, 2019

-

What are The Precautions for The Connecting Pipe of The Air Compressor?

Date: Sep 16, 2019

-

What are The Requirements for Water-Cooling Air Compressors?

Date: Oct 15, 2019

-

How to Ventilate the Air Compressor Room?

Date: Oct 29, 2019

-

What are The precautions for Installing The Main Circuit Cable of The Air Compressor?

Date: Nov 27, 2019

-

Analysis of Gumming and Carbon Deposit in Screw Air Compressor

Date: Dec 9, 2019

-

Advantages of Elang Oil Free Screw Air Compressor

Date: Dec 16, 2019

-

14 Tips for Compressor Operation

Date: Feb 14, 2020

-

ELANG 200kw Two-stage PM VSD Compressor Loading Flat Rack Container

Date: Mar 3, 2020

-

Why does Two-stage Screw Air Compressor Energy Saving?

Date: May 19, 2020

-

Elang Oil-free Air Compressor for Korean Instant Noodle Factory

Date: May 27, 2020

-

30m3/min 25bar Diesel Portable Compressor Delivery

Date: Jun 1, 2020