Steam turbine compressors are driven by power supply from and industrial compressor, compress the air in an compressing cavity and then pressurize the compressed air. They are primarily applied in power plants and steam reutilization industry, and can significantly improve the returns of enterprises for their energy conservation performance.

1)Steam temperature ≧250℃

2)Steam pressure ≧ 8bar, (10bar to 16bar would be good)

3)Steam input amount ≧ 3.2t/h

Introduction:

Steam turbine compressors are driven by power supply from and industrial compressor, compress the air in an compressing cavity and then pressurize the compressed air. They are primarily applied in power plants and steam reutilization industry, and can significantly improve the returns of enterprises for their energy conservation performance.

Take the application to power plants as example. The in-boiler high pressure steam is supplied to the stem turbine of the generating set to generate power to drive the power generator, and after that, the pressure of steam discharged from the steam turbine remains to be approximately 2Mpa. Before the use of a steam turbine compressor, such steam is cooled by the cooler and then transported to boiler in the form of water. The steam turbine compressor, however, draws on the steam from the steam turbine to drive the compressor to generate compressed air supplied to other equipment.

Product Performance:

1. Steam turbine compressors are provided with excellent governing system which is based on Germany Siemens technology and internationally cutting-edge. The governing system is safe and reliable, wide in regulating range, highly automatic, etc, able to realize remote automatic control of rotational speed and load and connect DCS system directly.

2. The bearings, both from and rear, of the steam turbine compressors and disposed in the inner oil tank and can be well lubricated and cooled, completely preventing the trouble of high oil temperature.

3. Speed governing valve: the speed governing is vital to normal operation of steam turbine compressor, and if the speed governing valve works flexibly and its useful life in turn underlie critically the performance of the governing system. Trough the improvement in its structure and processing techniques, the operating performance of the speed governing valve is made to be flexible, free to air leakage and have a long service life, etc.

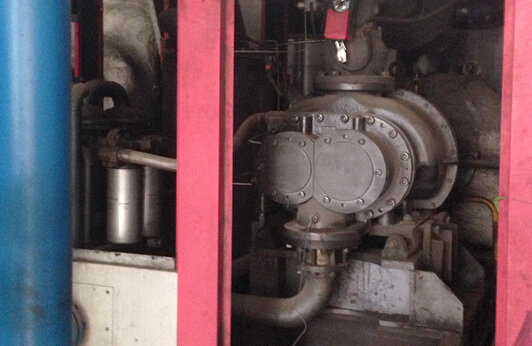

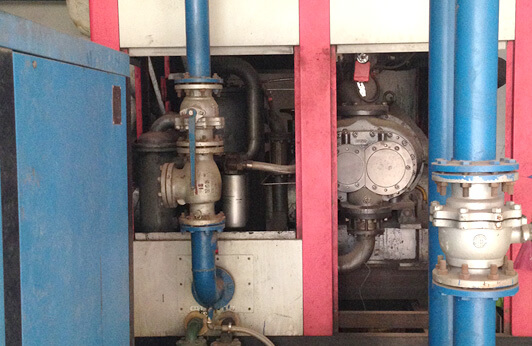

4. The air compressor and the steam turbine are driven by a coupling. The output shaft of the steam turbine is directly connected to the compressor air end on the frame via a resilient coupling. The internal system of the compressor unit comprises air intake system, air regulating system, oil system, cooling system, electric control system, safety and protection system, and all the components are installed onto the high -strength chassis.

5. Control system enables the air compressor to automatically regulate the capacity within a certain range to satisfy the requirements of users for changes in the air delivery.

6. PLC master controller manages and monitors the entire air compressor system, and for its simple man-machine interface, can well familiarize an operator with the specific operation status of the unit. In addition, this master controller has remote control function and relevant interface, thus enabling users to operate online and the management center to control a group of compressors at the same time.

Energy conservation and result evaluation:

Example: One 40m3/min common compressor is configured to require a power supply of 250KW, and operates with power consumption of 250×24=6000KW daily, that is, an annual power consumption of 2136000KW. Suppose the power plant generates power 1KW=RMB0.1 each day, and power consumption costs RMB213600 a year. If a steam turbine compressor is employed, 2136000KW power energy can be conserved, which means an economic result of RMB213600. Generally, a power plant requires 4-5 air compressor, and it suggests that a profit of around RMB 1 million can be achieved each year.

Customer Comments:

About Elang:

FAQ:

-

Q1.Why customer choose us?

A:ELANG INDUSTRIAL (SHANGHAI) CO., LTD., with 20 years old history, we are specialized in Rotary Screw Air Compressor. Germany Standard and over 10 years exporting experience help us won more than 50 loyal foreign agents. We warmly welcome your small trial order for quality or market test.

Q2.Are you a manufacturer or trading company?

A:We are professional manufacturer with big modern factory in Shanghai,China.Both OEM & ODM service can be accepted.

Q3.What’s your delivery time?

A:Generally 3 to 7 days, if urgently order, pls contact our sales in advance.

Q4.How long is your air compressor warranty?

A:One year for the whole machine and five years for screw air end, except consumble spare parts.

Q5.How long could your air compressor be used?

A:Generally, more than 10 years.

Q6. What's payment term?

A: T/T, L/C, D/P, Western Union, Paypal, Credit Card, and etc.

Also we could accept USD, RMB, Euro and other currency.

Q7.How about your customer service?

A:24 hours on-line service available. 48hours global problem sovled promise.

10+ professional overseas technical service team.

Q8.How about your after-sales service?

A:1. Provide customers with intallation and commissioning online instructions.

2. Well-trained engineers available to overseas service.

3. Worldwide agents and after service avaiable.arrange our engineers to help you training and installation.

| Model | ERC-175SW | ERC-250SW | ERC-330SW | ERC-420SW | ERC-470SW | ERC-550SW | ERC-600SW | ERC-670SW | ERC-800SW | |

| Type of cooling | A-Air cooling W-Water cooling | |||||||||

| Air delivery / Working pressure | m3/min/bar | 23.0/8 | 31.0/8 | 43.0/8 | 56.0/8 | 62.08/8 | 73.0/8 | 81.0/8 | 89.0/8 | 100.0/8 |

| 20.0/10 | 26.0/10 | 40.0/10 | 50.0/10 | 54.0/10 | 63.0/10 | 71.0/10 | 79.0/10 | 87.0/10 | ||

| 42.0/12.5 | 47.0/12.5 | 53.0/12.5 | 60.0/12.5 | 67.0/12.5 | 77.0/12.5 | |||||

| Motor power | KW | 132 | 250 | 250 | 315 | 355 | 400 | 450 | 500 | 600 |

| Steam turbine compressor power | KW | 160 | 250 | 320 | 400 | 450 | 500 | 600 | 600 | 750 |

| Rotation speed of steam turbine | r/min | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 |

| Steam output pressure of steam turbine | Mpa | 1.0-1.6 | 1.0-1.6 | 1.0-1.6 | 1.0-1.6 | 1.0-1.6 | 1.0-1.6 | 1.0-1.6 | 1.0-1.6 | 1.0-1.6 |

| Steam input temperature of steam turbine | ℃ | ≥250 | ≥250 | ≥250 | ≥250 | ≥250 | ≥250 | ≥250 | ≥250 | ≥300 |

| Steam air input | T/h | 3.2/10 | 5.2 | 6.55/5 | 8.2 | 10.3 | 10.3 | 12.5 | 12.5 | 13.6 |

| Steam discharge pressure of steam turbine | Mpa | 0.1-0.2 | 0.1-0.2 | 0.1-0.2 | 0.1-0.2 | 0.1-0.2 | 0.1-0.2 | 0.1-0.2 | 0.1-0.2 | 0.1-0.2 |

| Upon technical data are basic data, which can be made according to customer's requirements | ||||||||||

| Voltage | V/Hz | AC 380V/50HZ | ||||||||

| Noise | dB(A) | 72±5, tested according to the international standard GB/T4980-2003 | ||||||||

| Oil content of discharge air | <3ppm | |||||||||

| Temperature of discharge air | Ambient temperature + 15 ℃ | |||||||||

| Cooling water volume | L/min | 127 | 171 | 236 | 320 | 355 | 420 | 465 | 510 | 630 |

| Pipe connection diameter | DN80 | DN80 | DN100 | DN125 | DN150 | DN150 | DN175 | DN175 | DN200 | |