Food Grade Oil Injected Screw Air Compressor

Compared to using the oil lubricated compressor, the food grade compressor is more safety and also the price is more competitive than the oil free compressor, therefore food grade air compressor is a very good choice for food industry.

With the intensification of market competition, food companies in various countries have taken measures to improve the sanitation and safety of food and to improve the competitiveness of their products. In this food safety and quality battle, food grade air compressors are also a good choice.

In the past, most food companies chose industrial-grade lubricants for their machines as they often considered only the price. Although the price of industrial-grade lubricants is low, it can save costs for enterprises, but this product contains more heavy metals such as lead, arsenic, and mercury. Once it contaminates food, it will cause long-term and serious harm to human health. The lubricating oil used in food-grade lubricating oil compressors is non-toxic, harmless, hygienic and safe, and does not contain mineral hydrocarbons, nut oils and genetically modified ingredients in the raw materials, which will not harm the quality of food. Food grade compressor is widely suggest to replace the oil lubricated compressor.

Compared with more expensive oil free air compressors, food grade air compressors have lower cost and the food air compressors are really a good choice for many small and medium-sized enterprises.

If any questions or inquiry, warmly welcome to check with Elang food grade compressor.

Features:

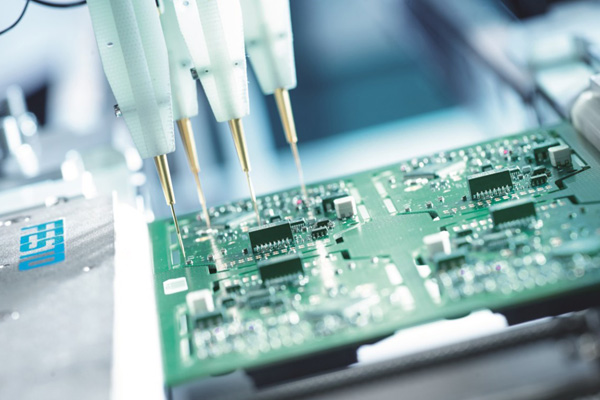

Intelligent control:

ABB high sensitivity high reliability, low failure.

Motor and air end:

Direct connect with high transmission efficiency .

Clear at a glance

The operation is simple ,thoughtful and powerful.

Cooler:

Copper material,high thermal effects,Ensure isothermal compression,it can work high-temperature conditions,the maximum temperature<45℃ in summer The lowest temperature in winter is +10.

Advantages:

- 1. A precisely-made central bracket is used to keep the motor aligned permanently with the air end.

- 2. A highly resilient coupling is adopted to make the compressor operate smoothly, and the elastomer is long in useful life.

- 3. The discharge pipe is double-wall corrugated pipe, and the oil way uses a special high-pressure hose which is resistant to temperature up to 125℃.

- 4. For the extremely high temperature conditions in some districts, the large-area plate heat. exchange and high-efficiency water chiller are used.

Highly-quality shaft coupling elastic body can buffer and compensate for the imbalanced moment of operation. The elastomer is designed into and involute cambered surface, which effectively avoids stress concentration and improve the buffering effect of the elastomer to increase its bearing capacity. In addition, the high-quality materials ensure excellent durability for the elastomer and can better absorb the vibration arising from the rotation to remove noise.

| Model | Working Pressure | Air Delivery | Motor Power | Type of Driving | Type of Cooling | Dimension(mm) |

Weight (kg) |

Output pipe Diameter |

||||||

| psig | bar | cfm | m3/min | kw/hp | L | W | H | |||||||

| ERC-10SA | 100 | 7 | 38.8 | 1.1 | 7.5/10 | Belt driven |

Air Cooling / Water Cooling |

850 | 640 | 880 | 350 | 3/4" | ||

| 116 | 8 | 35.3 | 1 | |||||||||||

| 145 | 10 | 30.0 | 0.85 | |||||||||||

| 181 | 12.5 | 24.7 | 0.7 | |||||||||||

| ERC-15SA | 100 | 7 | 63.6 | 1.8 | 11/15 | 1150 | 750 | 1180 | 450 | 1" | ||||

| 116 | 8 | 58.3 | 1.65 | |||||||||||

| 145 | 10 | 53.0 | 1.5 | |||||||||||

| 181 | 12.5 | 45.9 | 1.3 | |||||||||||

| ERC-20SA | 100 | 7 | 84.7 | 2.4 | 15/20 | 1150 | 750 | 1180 | 460 | 1" | ||||

| 116 | 8 | 77.7 | 2.2 | |||||||||||

| 145 | 10 | 74.2 | 2.1 | |||||||||||

| 181 | 12.5 | 63.6 | 1.8 | |||||||||||

| ERC-25SA | 100 | 7 | 109.5 | 3.1 | 18.5/25 | 1200 | 880 | 1450 | 620 | 1" | ||||

| 116 | 8 | 102.4 | 2.9 | |||||||||||

| 145 | 10 | 95.3 | 2.7 | |||||||||||

| 181 | 12.5 | 81.2 | 2.3 | |||||||||||

| ERC-30SA | 100 | 7 | 134.2 | 3.8 | 22/30 | 1200 | 880 | 1450 | 640 | 1" | ||||

| 116 | 8 | 127.1 | 3.6 | |||||||||||

| 145 | 10 | 113.0 | 3.2 | |||||||||||

| 181 | 12.5 | 88.3 | 2.5 | |||||||||||

| ERC-40SA | 100 | 7 | 187.1 | 5.3 | 30/40 | 1250 | 1000 | 1360 | 900 | 11/4" | ||||

| 116 | 8 | 176.6 | 5 | |||||||||||

| 145 | 10 | 151.8 | 4.3 | |||||||||||

| 181 | 12.5 | 127.1 | 3.6 | |||||||||||

| ERC-50SA | 100 | 7 | 233.0 | 6.6 | 37/50 | 1350 | 1000 | 1640 | 1060 | 11/4" | ||||

| 116 | 8 | 218.9 | 6.2 | |||||||||||

| 145 | 10 | 201.3 | 5.7 | |||||||||||

| 181 | 12.5 | 162.4 | 4.6 | |||||||||||

| ERC-60SA | 100 | 7 | 282.5 | 8 | 45/60 | 1300 | 1000 | 1470 | 1150 | 11/2" | ||||

| 116 | 8 | 271.9 | 7.7 | |||||||||||

| 145 | 10 | 243.6 | 6.9 | |||||||||||

| 181 | 12.5 | 211.9 | 6 | |||||||||||

| ERC-75SA | 100 | 7 | 370.8 | 10.5 | 55/75 | 1950 | 1320 | 1570 | 1750 | 2" | ||||

| 116 | 8 | 346.0 | 9.8 | |||||||||||

| 145 | 10 | 307.2 | 8.7 | |||||||||||

| 181 | 12.5 | 257.8 | 7.3 | |||||||||||

| ERC-100SA | 100 | 7 | 480.2 | 13.6 | 75/100 | 1950 | 1320 | 1570 | 1840 | 2" | ||||

| 116 | 8 | 459.0 | 13 | |||||||||||

| 145 | 10 | 399.0 | 11.3 | |||||||||||

| 181 | 12.5 | 356.6 | 10.1 | |||||||||||

| ERC-120SA | 100 | 7 | 572.0 | 16.2 | 90/120 | 2100 | 1320 | 1700 | 2030 | 2" | ||||

| 116 | 8 | 543.8 | 15.4 | |||||||||||

| 145 | 10 | 466.1 | 13.2 | |||||||||||

| 181 | 12.5 | 395.5 | 11.2 | |||||||||||

|

Motor Efficiency Class: Ultraefficient/IE3/IE2 as per your required Motor Protection Class: IP23/IP54/IP55 or as per your required Certification: CE/ISO9001/TUV/UL/SGS/ASME Voltage: 380V/3PH/50HZ/60HZ, 220V/3PH/50HZ/60HZ, 400V/3PH/50HZ/60HZ, 440V/3PH/50HZ/60HZ, 415V/3PH/50HZ/60HZ, 230V/3PH/50HZ/60HZ, dual voltage is also ok |

||||||||||||||