| Model | Working Pressure | Air Delivery | Motor Power | Type of Driving | Type of Cooling | Dimension(mm) | Weight(kg) | Output pipe Diameter | ||||||

| psig | bar | cfm | m3/min | kw/hp | L | W | H | |||||||

|

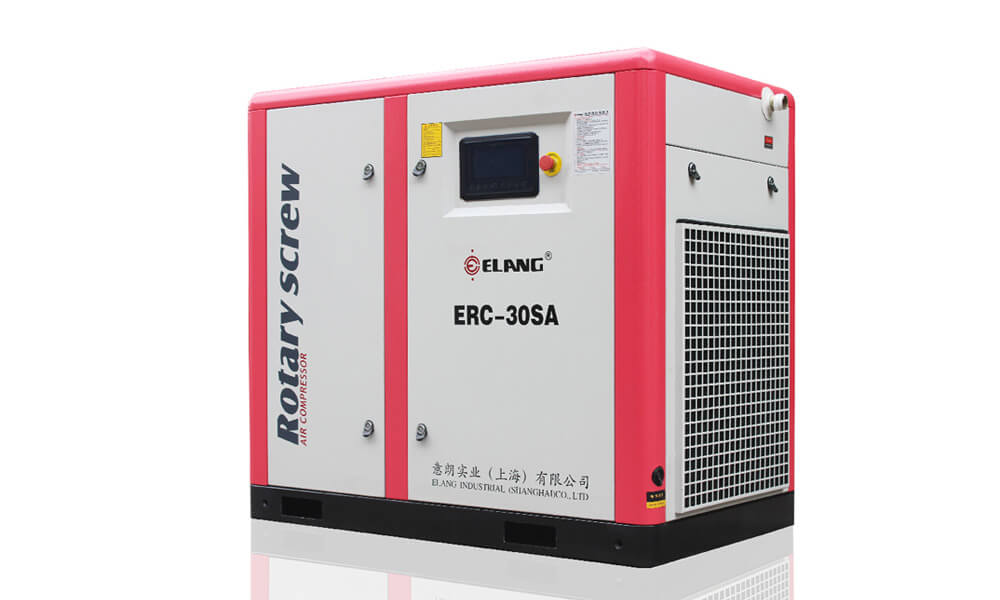

ERC-25SA ERC-25SW |

100 | 7 | 109.5 | 3.1 | 18.5/25 | Direct driven |

Air Cooling / Water Cooling |

1380 | 850 | 1150 | 640 | 11/4" | ||

| 116 | 8 | 102.4 | 2.9 | |||||||||||

| 145 | 10 | 95.4 | 2.7 | |||||||||||

| 181 | 13 | 81.2 | 2.3 | |||||||||||

|

ERC-30SA ERC-30SW |

100 | 7 | 134.2 | 3.8 | 22/30 | 1380 | 850 | 1150 | 640 | 11/4" | ||||

| 116 | 8 | 127.1 | 3.6 | |||||||||||

| 145 | 10 | 113.0 | 3.2 | |||||||||||

| 181 | 13 | 88.3 | 2.5 | |||||||||||

|

ERC-40SA ERC-40SW |

100 | 7 | 187.1 | 5.3 | 30/40 | 1450 | 900 | 1220 | 900 | 11/4" | ||||

| 116 | 8 | 176.6 | 5 | |||||||||||

| 145 | 10 | 151.8 | 4.3 | |||||||||||

| 181 | 13 | 127.1 | 3.6 | |||||||||||

|

ERC-50SA ERC-50SW |

100 | 7 | 233.0 | 6.6 | 37/50 | 1595 | 1000 | 1365 | 1060 | 11/2" | ||||

| 116 | 8 | 218.9 | 6.2 | |||||||||||

| 145 | 10 | 201.3 | 5.7 | |||||||||||

| 181 | 13 | 162.4 | 4.6 | |||||||||||

|

ERC-60SA ERC-60SW |

100 | 7 | 282.5 | 8 | 45/60 | 1595 | 1000 | 1450 | 1150 | 11/2" | ||||

| 116 | 8 | 271.9 | 7.7 | |||||||||||

| 145 | 10 | 243.6 | 6.9 | |||||||||||

| 181 | 13 | 211.9 | 6 | |||||||||||

|

ERC-75SA ERC-75SW |

100 | 7 | 370.8 | 10.5 | 55/75 | 2100 | 1250 | 1700 | 1750 | 2" | ||||

| 116 | 8 | 346.0 | 9.8 | |||||||||||

| 145 | 10 | 307.2 | 8.7 | |||||||||||

| 181 | 13 | 257.8 | 7.3 | |||||||||||

|

ERC-100SA ERC-100SW |

100 | 7 | 480.2 | 13.6 | 75/100 | 2100 | 1250 | 1700 | 1840 | 2" | ||||

| 116 | 8 | 459.0 | 13 | |||||||||||

| 145 | 10 | 399.0 | 11.3 | |||||||||||

| 181 | 13 | 356.6 | 10.1 | |||||||||||

|

ERC-120SA ERC-120SW |

100 | 7 | 572.0 | 16.2 | 90/120 | 2100 | 1250 | 1700 | 2030 | 2" | ||||

| 116 | 8 | 543.8 | 15.4 | |||||||||||

| 145 | 10 | 466.1 | 13.2 | |||||||||||

| 181 | 13 | 395.5 | 11.2 | |||||||||||

|

ERC-150SA ERC-150SW |

100 | 7 | 734.4 | 20.8 | 110/150 | 2545 | 1450 | 1900 | 2920 | DN65 | ||||

| 116 | 8 | 688.5 | 19.5 | |||||||||||

| 145 | 10 | 582.6 | 16.5 | |||||||||||

| 181 | 13 | 483.7 | 13.7 | |||||||||||

|

ERC-175SA ERC-175SW |

100 | 7 | 847.4 | 24 | 132/175 | 2545 | 1450 | 1900 | 3200 | DN65 | ||||

| 116 | 8 | 812.1 | 23 | |||||||||||

| 145 | 10 | 706.2 | 20 | |||||||||||

| 181 | 13 | 547.3 | 15.5 | |||||||||||

|

ERC-200SA ERC-200SW |

100 | 7 | 981.6 | 27.8 | 160/200 | 2790 | 1550 | 2000 | 3600 | DN65 | ||||

| 116 | 8 | 918.1 | 26 | |||||||||||

| 145 | 10 | 829.8 | 23.5 | |||||||||||

| 181 | 13 | 688.5 | 19.5 | |||||||||||

|

ERC-250SA ERC-250SW |

100 | 7 | 1147.6 | 32.5 | 185/250 | 2790 | 1550 | 2000 | 3780 | DN65 | ||||

| 116 | 8 | 1094.6 | 31 | |||||||||||

| 145 | 10 | 918.1 | 26 | |||||||||||

| 181 | 13 | 762.7 | 21.6 | |||||||||||

|

ERC-270SA ERC-270SW |

100 | 7 | 1218.2 | 34.5 | 200/270 | 2850 | 1700 | 2000 | 4400 | DN80 | ||||

| 116 | 8 | 1165.2 | 33 | |||||||||||

| 145 | 10 | 988.7 | 28 | |||||||||||

| 181 | 13 | 829.8 | 23.5 | |||||||||||

|

ERC-300SA ERC-300SW |

100 | 7 | 1341.8 | 38 | 220/300 | 3150 | 2000 | 2120 | 4930 | DN100 | ||||

| 116 | 8 | 1288.8 | 36.5 | |||||||||||

| 145 | 10 | 1129.9 | 32 | |||||||||||

| 181 | 13 | 953.4 | 27 | |||||||||||

|

ERC-330SA ERC-330SW |

100 | 7 | 1518.3 | 43 | 250/330 | 3150 | 2000 | 2120 | 5450 | DN100 | ||||

| 116 | 8 | 1430.1 | 40.5 | |||||||||||

| 145 | 10 | 1288.8 | 36.5 | |||||||||||

| 181 | 13 | 1129.9 | 32 | |||||||||||

|

ERC-375SA ERC-375SW |

100 | 7 | 1818.5 | 51.5 | 280/375 | 4000 | 2000 | 2100 | 6150 | DN125 | ||||

| 116 | 8 | 1765.5 | 50 | |||||||||||

| 145 | 10 | 1589.0 | 45 | |||||||||||

| 181 | 13 | 1306.5 | 37 | |||||||||||

|

ERC-420SA ERC-420SW |

100 | 7 | 1977.4 | 56 | 315/420 | 4600 | 2300 | 2400 | 7500 | DN125 | ||||

| 116 | 8 | 1942.1 | 55 | |||||||||||

| 145 | 10 | 1730.2 | 49 | |||||||||||

| 181 | 13 | 1447.7 | 41 | |||||||||||

|

ERC-470SA ERC-470SW |

100 | 7 | 2259.8 | 64 | 355/470 | 4600 | 2300 | 2400 | 8100 | DN150 | ||||

| 116 | 8 | 2189.2 | 62 | |||||||||||

| 145 | 10 | 1906.7 | 54 | |||||||||||

| 181 | 13 | 1624.3 | 46 | |||||||||||

|

ERC-550SA ERC-550SW |

100 | 7 | 2577.6 | 73 | 400/550 | 5000 | 2350 | 2400 | 8400 | DN150 | ||||

| 116 | 8 | 2471.7 | 70 | |||||||||||

| 145 | 10 | 2153.9 | 61 | |||||||||||

| 181 | 13 | 1836.1 | 52 | |||||||||||

|

ERC-600SA ERC-600SW |

100 | 7 | 2860.1 | 81 | 450/600 | 5500 | 2590 | 2800 | 9000 | DN150 | ||||

| 116 | 8 | 2789.5 | 79 | |||||||||||

| 145 | 10 | 2471.7 | 70 | |||||||||||

| 181 | 13 | 2083.3 | 59 | |||||||||||

|

ERC-670SA ERC-670SW |

100 | 7 | 3142.6 | 89 | 500/670 | 5500 | 2590 | 2800 | 9500 | DN200 | ||||

| 116 | 8 | 3072.0 | 87 | |||||||||||

| 145 | 10 | 2718.9 | 77 | |||||||||||

| 181 | 13 | 2365.8 | 67 | |||||||||||

|

ERC-750SA ERC-750SW |

100 | 7 | 3601.6 | 102 | 560/750 | 6500 | 2700 | 3000 | 10000 | DN200 | ||||

| 116 | 8 | 3460.4 | 98 | |||||||||||

| 145 | 10 | 3072.0 | 87 | |||||||||||

| 181 | 13 | 2718.9 | 77 | |||||||||||

|

Motor Efficiency Class: Ultraefficient/IE3/IE2 as per your required Motor Protection Class: IP23/IP54/IP55 or as per your required Certification: CE/ISO9001/TUV/UL/SGS/ASME Voltage: 380V/3PH/50HZ/60HZ, 220V/3PH/50HZ/60HZ, 400V/3PH/50HZ/60HZ, 440V/3PH/50HZ/60HZ, 415V/3PH/50HZ/60HZ, 230V/3PH/50HZ/60HZ, dual voltage is also ok |

||||||||||||||

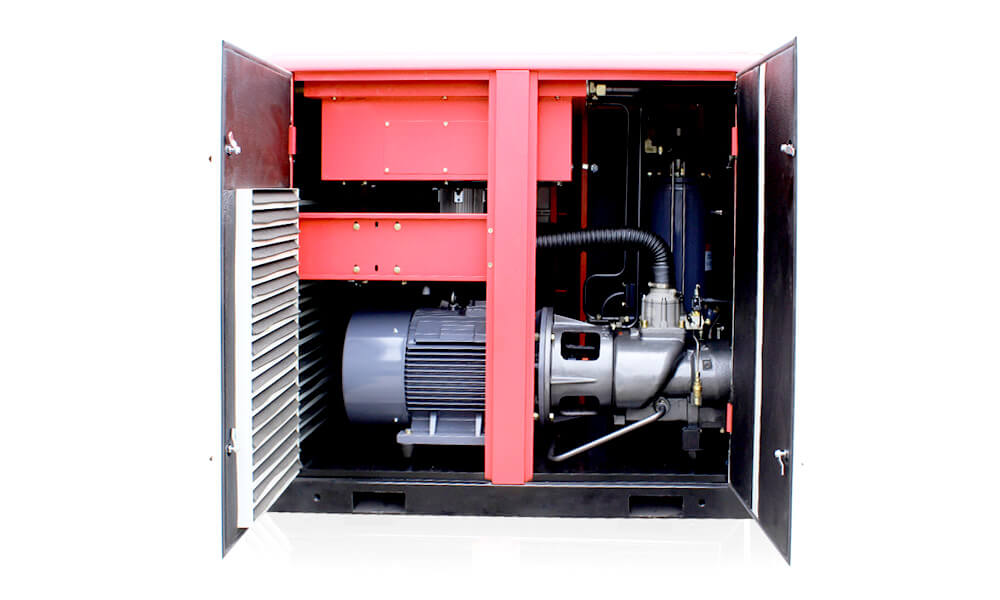

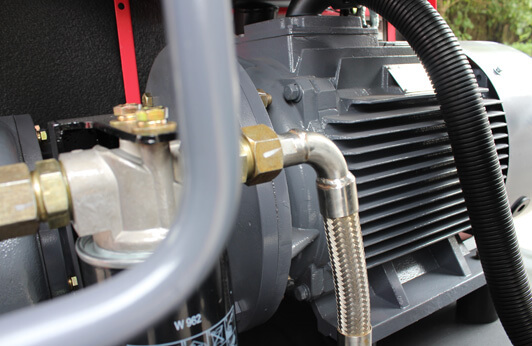

Highly-quality shaft coupling elastic body can buffer and compensate for the imbalanced moment of operation. The elastomer is designed into and involute cambered surface, which effectively avoids stress concentration and improve the buffering effect of the elastomer to increase its bearing capacity. In addition, the high-quality materials ensure excellent durability for the elastomer and can better absorb the vibration arising from the rotation to remove noise. Since no wearing parts are used for the double-screw compressor air end, it can operate for up to 40000-80000 hours between failure if well maintained.

Features:

- 1. A precisely-made central bracket is used to keep the motor aligned permanently with the air end.

- 2. A highly resilient coupling is adopted to make the compressor operate smoothly, and the elastomer is long in useful life.

- 3. The discharge pipe is double-wall corrugated pipe, and the oil way uses a special high-pressure hose which is resistant to temperature up to 125℃.

- 4. For the extremely high temperature conditions in some districts, the large-area plate heat. exchange and high-efficiency water chiller are used.

Highly-quality shaft coupling elastic body can buffer and compensate for the imbalanced moment of operation. The elastomer is designed into and involute cambered surface, which effectively avoids stress concentration and improve the buffering effect of the elastomer to increase its bearing capacity. In addition, the high-quality materials ensure excellent durability for the elastomer and can better absorb the vibration arising from the rotation to remove noise.

Advantage:

1.Large displacement: Displacement 10% higher than ordinary piston compressor.

2. Energy-saving: Compared with piston air compressor, this series of models for the new national standard two energy efficiency products, excellent energy saving.

3. Easy to operate: 24 hours unattended all day work, free load automatically start, full load automatically shut down.

4. Strong stability: Under long time working, displacement and pressure stable, no crash phenomenon, low failure rate.

Application:

Hot Sale Of Direct Driven Series:

Customer Comments:

About Elang:

FAQ:

-

Q1.Why customer choose us?

A:ELANG INDUSTRIAL (SHANGHAI) CO., LTD., with 20 years old history, we are specialized in Rotary Screw Air Compressor. Germany Standard and over 10 years exporting experience help us won more than 50 loyal foreign agents. We warmly welcome your small trial order for quality or market test.

Q2.Are you a manufacturer or trading company?

A:We are professional manufacturer with big modern factory in Shanghai,China.Both OEM & ODM service can be accepted.

Q3.What’s your delivery time?

A:Generally 3 to 7 days, if urgently order, pls contact our sales in advance.

Q4.How long is your air compressor warranty?

A:One year for the whole machine and five years for screw air end, except consumble spare parts.

Q5.How long could your air compressor be used?

A:Generally, more than 10 years.

Q6. What's payment term?

A: T/T, L/C, D/P, Western Union, Paypal, Credit Card, and etc.

Also we could accept USD, RMB, Euro and other currency.

Q7.How about your customer service?

A:24 hours on-line service available. 48hours global problem sovled promise.

10+ professional overseas technical service team.

Q8.How about your after-sales service?

A:1. Provide customers with intallation and commissioning online instructions.

2. Well-trained engineers available to overseas service.

3. Worldwide agents and after service avaiable.arrange our engineers to help you training and installation.