Recommended Air Compressor used for Color Sorting Machine

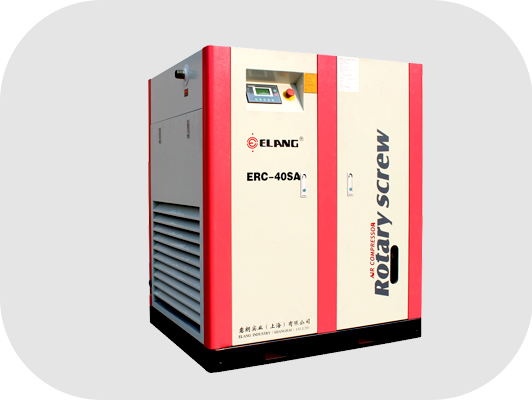

Direct Driven Screw Air Compressor

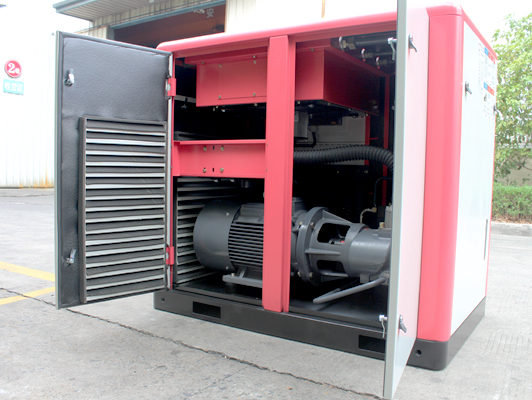

Highly-quality shaft coupling elastic body can buffer and compensate for the imbalanced moment of operation. The elastomer is designed into and involute cambered surface, which effectively avoids stress concentration and improve the buffering effect of the elastomer to increase its bearing capacity. In addition, the high-quality materials ensure excellent durability for the elastomer and can better absorb the vibration arising from the rotation to remove noise. Since no wearing parts are used for the double-screw compressor air end, it can operate for up to 40000-80000 hours between failure if well maintained.

Features:

- 1. A precisely-made central bracket is used to keep the motor aligned permanently with the air end.

- 2. A highly resilient coupling is adopted to make the compressor operate smoothly, and the elastomer is long in useful life.

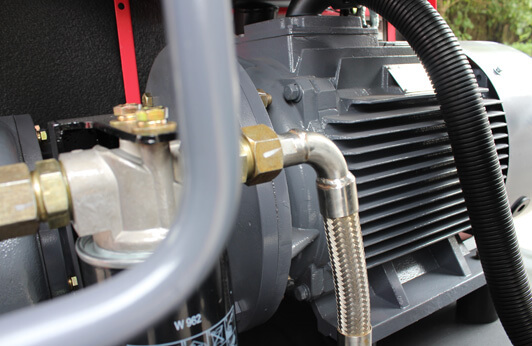

- 3. The discharge pipe is double-wall corrugated pipe, and the oil way uses a special high-pressure hose which is resistant to temperature up to 125℃.

- 4. For the extremely high temperature conditions in some districts, the large-area plate heat. exchange and high-efficiency water chiller are used.

Highly-quality shaft coupling elastic body can buffer and compensate for the imbalanced moment of operation. The elastomer is designed into and involute cambered surface, which effectively avoids stress concentration and improve the buffering effect of the elastomer to increase its bearing capacity. In addition, the high-quality materials ensure excellent durability for the elastomer and can better absorb the vibration arising from the rotation to remove noise.

Advantage:

1.Large displacement: Displacement 10% higher than ordinary piston compressor.

2. Energy-saving: Compared with piston air compressor, this series of models for the new national standard two energy efficiency products, excellent energy saving.

3. Easy to operate: 24 hours unattended all day work, free load automatically start, full load automatically shut down.

4. Strong stability: Under long time working, displacement and pressure stable, no crash phenomenon, low failure rate.

Belt Driven Screw Air Compressor

Belt driven, which allows the speed of the rotor to be changed by different diameter pulleys.

1. The belt tension for each operating condition is optimized

2. By avoiding excessive start-up tension, greatly extending the belt working life

3. Always ensure the correct pulley connection

4. Replace the belt is very easy and fast, and do not need to adjust the original settings 5. The whole belt driven system safe and trouble-free operation.

Advantage:

Control Panel:

Intelligent microcomputer-based control technology can monitor and control in all aspects the complete machine following your instruction. Remote control realizes unattended operation, and the user-friendly human-machine interface displays instructions and parameters in written form. Also, it can function to self diagnose faults, give warning and automatically regulate the capacity.

Oil filter:

Rotary filters are applied to completely remove the impurities in the lubricating oil, easy to replace and free of oil impregnate.

Cooler:

It is designed for low temperature difference to increase heat exchange area, and ideal to be applied to high-temperature and high-humidity operating environment.

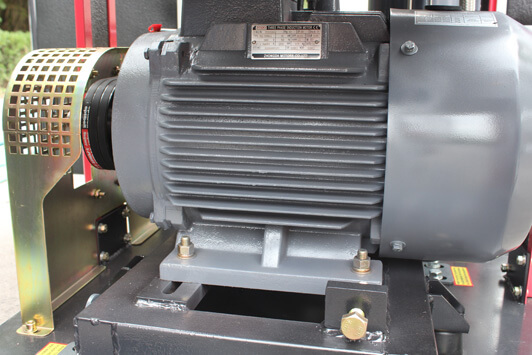

Motor:

First-class motors are adopted, with the level of protection being IP54 and insulation level being F.

Acoustic enclosure:

It is designed into fully-closed mute box, in which sound-absorbing sponge are attached for effective absorption of noise, thereby making the noise 3-5dB(A) lower than that made by the compressors of the same kind. It is reasonably structured overall and very easy to maintain and repair.

Specifications:

| Model | Working Pressure | Air Delivery | Motor Power | Type of Driving | Type of Cooling | Dimension(mm) |

Weight (kg) |

Output pipe Diameter |

||||||

| psig | bar | cfm | m3/min | kw/hp | L | W | H | |||||||

| ERC-10SA | 100 | 7 | 38.8 | 1.1 | 7.5/10 |

Belt Driven / Direct Driven |

Air Cooling / Water Cooling |

850 | 640 | 880 | 350 | 3/4" | ||

| 116 | 8 | 35.3 | 1 | |||||||||||

| 145 | 10 | 30.0 | 0.85 | |||||||||||

| 181 | 12.5 | 24.7 | 0.7 | |||||||||||

| ERC-15SA | 100 | 7 | 63.6 | 1.8 | 11/15 | 1150 | 750 | 1180 | 450 | 1" | ||||

| 116 | 8 | 58.3 | 1.65 | |||||||||||

| 145 | 10 | 53.0 | 1.5 | |||||||||||

| 181 | 12.5 | 45.9 | 1.3 | |||||||||||

| ERC-20SA | 100 | 7 | 84.7 | 2.4 | 15/20 | 1150 | 750 | 1180 | 460 | 1" | ||||

| 116 | 8 | 77.7 | 2.2 | |||||||||||

| 145 | 10 | 74.2 | 2.1 | |||||||||||

| 181 | 12.5 | 63.6 | 1.8 | |||||||||||

| ERC-25SA | 100 | 7 | 109.5 | 3.1 | 18.5/25 | 1200 | 880 | 1450 | 620 | 1" | ||||

| 116 | 8 | 102.4 | 2.9 | |||||||||||

| 145 | 10 | 95.3 | 2.7 | |||||||||||

| 181 | 12.5 | 81.2 | 2.3 | |||||||||||

| ERC-30SA | 100 | 7 | 134.2 | 3.8 | 22/30 | 1200 | 880 | 1450 | 640 | 1" | ||||

| 116 | 8 | 127.1 | 3.6 | |||||||||||

| 145 | 10 | 113.0 | 3.2 | |||||||||||

| 181 | 12.5 | 88.3 | 2.5 | |||||||||||

| ERC-40SA | 100 | 7 | 187.1 | 5.3 | 30/40 | 1250 | 1000 | 1360 | 900 | 11/4" | ||||

| 116 | 8 | 176.6 | 5 | |||||||||||

| 145 | 10 | 151.8 | 4.3 | |||||||||||

| 181 | 12.5 | 127.1 | 3.6 | |||||||||||

| ERC-50SA | 100 | 7 | 233.0 | 6.6 | 37/50 | 1350 | 1000 | 1640 | 1060 | 11/4" | ||||

| 116 | 8 | 218.9 | 6.2 | |||||||||||

| 145 | 10 | 201.3 | 5.7 | |||||||||||

| 181 | 12.5 | 162.4 | 4.6 | |||||||||||

| ERC-60SA | 100 | 7 | 282.5 | 8 | 45/60 | 1300 | 1000 | 1470 | 1150 | 11/2" | ||||

| 116 | 8 | 271.9 | 7.7 | |||||||||||

| 145 | 10 | 243.6 | 6.9 | |||||||||||

| 181 | 12.5 | 211.9 | 6 | |||||||||||

| ERC-75SA | 100 | 7 | 370.8 | 10.5 | 55/75 | 1950 | 1320 | 1570 | 1750 | 2" | ||||

| 116 | 8 | 346.0 | 9.8 | |||||||||||

| 145 | 10 | 307.2 | 8.7 | |||||||||||

| 181 | 12.5 | 257.8 | 7.3 | |||||||||||

|

Motor Efficiency Class: Ultraefficient/IE3/IE2 as per your required Motor Protection Class: IP23/IP54/IP55 or as per your required Certification: CE/ISO9001/TUV/UL/SGS/ASME Voltage: 380V/3PH/50HZ/60HZ, 220V/3PH/50HZ/60HZ, 400V/3PH/50HZ/60HZ, 440V/3PH/50HZ/60HZ, 415V/3PH/50HZ/60HZ, 230V/3PH/50HZ/60HZ, dual voltage is also ok |

||||||||||||||