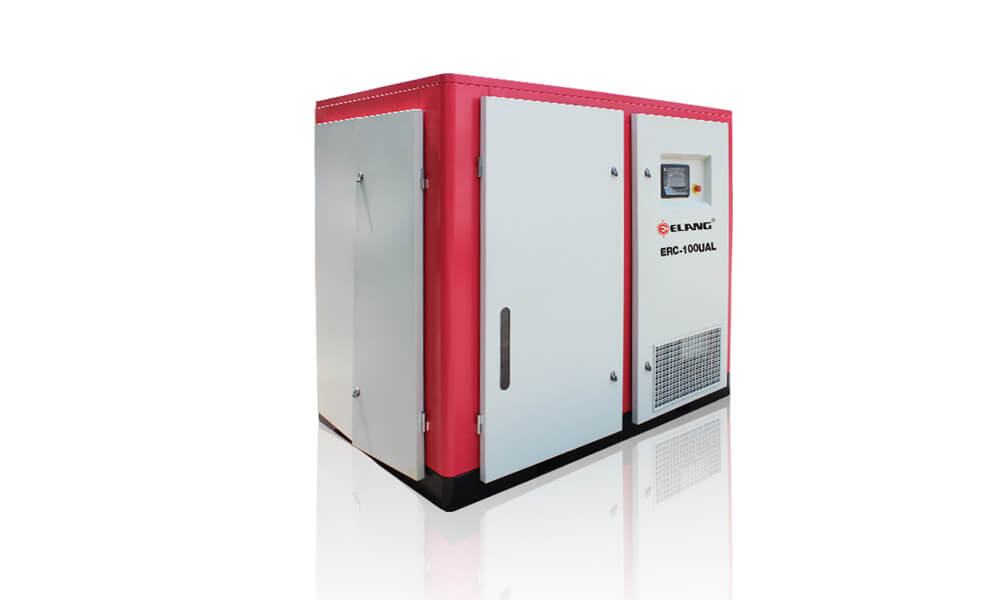

High Pressures Double Screw Air Compressor is a kind of oil-injected double screw air compressor with screw air end of high quality high pressure single-stage or two-stage type. Reliable perfomance, excellent quality, enviromental protection and energy-saving. Widely applied to the industries of mine projects, medical, food, electronics, chemical plant, mechanical and so on.

One type: Air delivery 6-34 m3/min, working pressure 25bar

The other type: Air delivery 5.5m3/min, working pressure 40bar

Advantages:

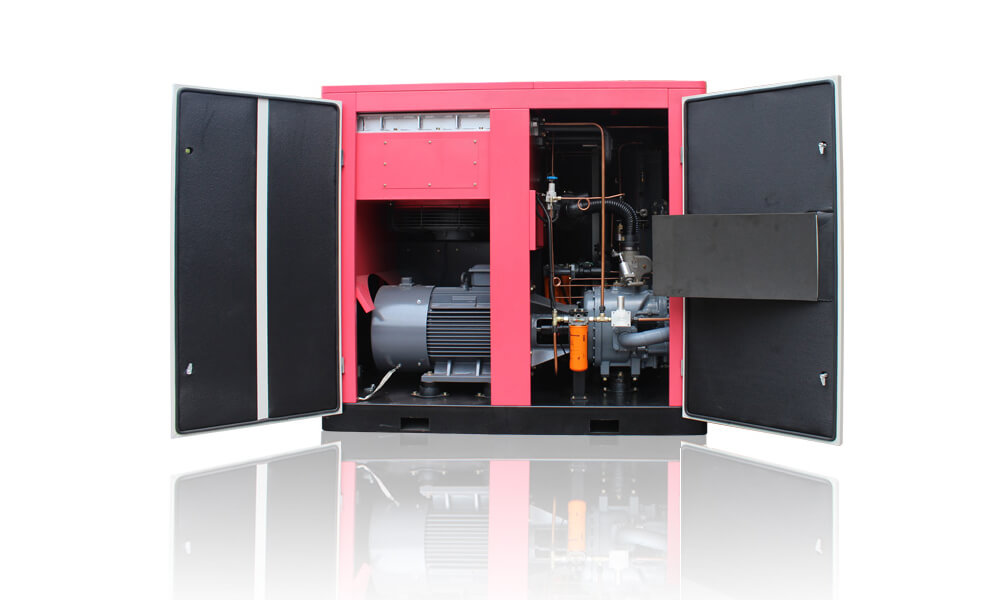

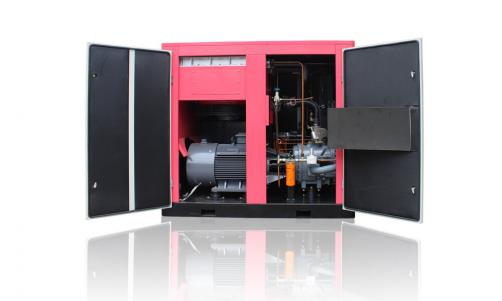

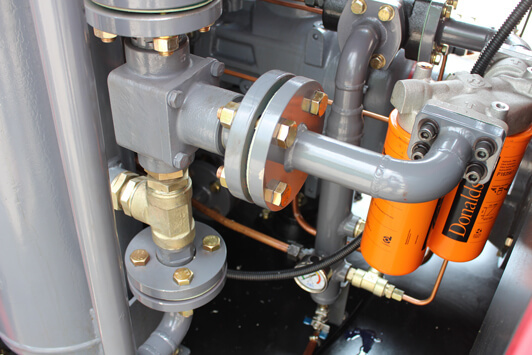

Perfect screw air end desigh parameter, accurate calculation of heat balance and linear expansion coefficient, high volume efficiency and advanced process flow. Superior product, sophisticated processing and manufacturing, and precision coordination, that can reach high efficiency and best compression ratio. The thrust bearing and radial bearing with better anti-abrasion function have more strong axial carrying capacity and stable running performance. The new inter-stage, cooling system make the compression ratio between two-stage compression higher, improve compressor efficiency, lower power consumption, save energy and protect enviroment, The wide application of unique sealing technology in the screw air end make reliability more higher and maintenance more convenient.

Powerful motor with SKF precision bearings and F insulation grade is of high protection motor, which is safe and reliable, high energy efficiency.Motor rich capacity can bear continous full-load operation without failure under all kinds of bad weather condition.

With excellent control system and ultra-strong safety protection function, the micro-computer controller of screw air compressor is the new generation high technology product developed by ELANG. It has the functions of controlling, communicating, ulttra-strong safety protection, remote control and nulti-computer control.

Customer Comments:

About Elang:

FAQ:

-

Q1.Why customer choose us?

A:ELANG INDUSTRIAL (SHANGHAI) CO., LTD., with 20 years old history, we are specialized in Rotary Screw Air Compressor. Germany Standard and over 10 years exporting experience help us won more than 50 loyal foreign agents. We warmly welcome your small trial order for quality or market test.

Q2.Are you a manufacturer or trading company?

A:We are professional manufacturer with big modern factory in Shanghai,China.Both OEM & ODM service can be accepted.

Q3.What’s your delivery time?

A:Generally 3 to 7 days, if urgently order, pls contact our sales in advance.

Q4.How long is your air compressor warranty?

A:One year for the whole machine and five years for screw air end, except consumble spare parts.

Q5.How long could your air compressor be used?

A:Generally, more than 10 years.

Q6. What's payment term?

A: T/T, L/C, D/P, Western Union, Paypal, Credit Card, and etc.

Also we could accept USD, RMB, Euro and other currency.

Q7.How about your customer service?

A:24 hours on-line service available. 48hours global problem sovled promise.

10+ professional overseas technical service team.

Q8.How about your after-sales service?

A:1. Provide customers with intallation and commissioning online instructions.

2. Well-trained engineers available to overseas service.

3. Worldwide agents and after service avaiable.arrange our engineers to help you training and installation.

| Model | Working Pressure | Air Delivery | Motor Power | Type of Cooling | Compression stage | Dimension(mm) | Weight | Output pipe Diameter | ||||

| psig | bar | cfm | m3/min | kw/hp | L | W | H | kg | ||||

| ERC-60UAL | 232 | 16 | 183.6 | 5.2 | 45/60 | Air Cooling | 1 | 1450 | 1100 | 1570 | 1800 | DN40 |

| ERC-100UAL | 232 | 16 | 303.6 | 8.6 | 75/100 | 1 | 1950 | 1150 | 1700 | 2100 | DN40 | |

| ERC-150UAL | 246 | 17 | 388.4 | 11 | 110/150 | 1 | 2500 | 1500 | 1900 | 3500 | DN50 | |

| 362 | 25 | 370.8 | 10.5 | 2 | ||||||||

| ERC-175UAL | 246 | 17 | 459.0 | 13 | 132/175 | 1 | 2500 | 1500 | 1900 | 3500 | DN50 | |

| 362.5 | 25 | 423.7 | 12 | 2 | / | DN50 | ||||||

| ERC-200UAL | 261 | 18 | 653.2 | 18.5 | 160/200 | 2 | 2750 | 1550 | 1950 | 4800 | DN65 | |

| 580 | 40 | 423.7 | 12 | 2 | ||||||||

| ERC-250UAL | 580 | 40 | 441.4 | 12.5 | 185/250 | 2 | 2650 | 1600 | 1950 | 3780 | DN40 | |

| ERC-270UAL | 246 | 17 | 776.8 | 22 | 200/270 | 1 | 2850 | 1750 | 2000 | 4800 | DN65 | |

| 290 | 20 | 741.5 | 21 | 2 | 5000 | |||||||

| ERC-315UAL | 290 | 20 | 847.4 | 24 | 235/315 | 2 | 4000 | 2000 | 2100 | 7000 | DN65 | |

| ERC-330UAL | 246 | 17 | 918.0 | 26 | 250/330 | 1 | 3150 | 2000 | 2000 | 5450 | DN80 | |

| ERC-375UAL | 362 | 25 | 882.8 | 25 | 280/375 | 2 | 4000 | 2000 | 2100 | 7000 | DN65 | |

| 435 | 30 | 805.1 | 22.8 | DN50 | ||||||||

| 580 | 40 | 706.2 | 20 | 6000 | ||||||||

| ERC-470UAL | 362 | 25 | 1165.2 | 33 | 355/470 | 2 | 4600 | 2300 | 2400 | 8000 | DN65 | |

| 290 | 20 | 1235.8 | 35 | 9000 | DN80 | |||||||

|

Motor Efficiency Class: Ultraefficient/IE3/IE2 as per your required Motor Protection Class: IP23/IP54/IP55 or as per your required Certification: CE/ISO9001/TUV/UL/SGS/ASME Voltage: 380V/3PH/50HZ/60HZ, 220V/3PH/50HZ/60HZ, 400V/3PH/50HZ/60HZ, 440V/3PH/50HZ/60HZ, 415V/3PH/50HZ/60HZ, 230V/3PH/50HZ/60HZ, dual voltage is also ok |

||||||||||||