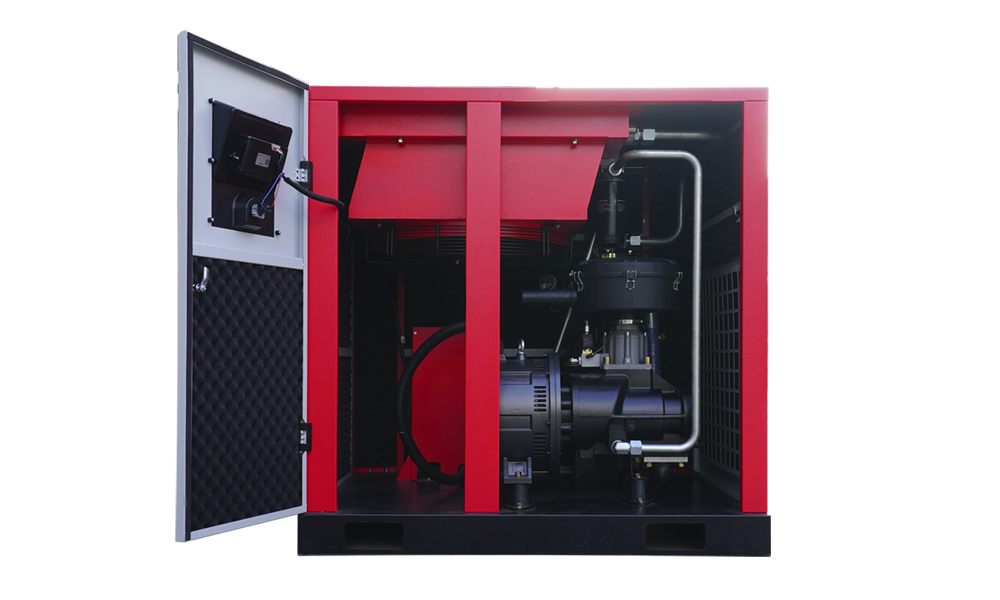

ERE Series Screw Air Compressor

...

Complying with the development trend of the market and trade, and to meet customer demand at home and abroad, Elang is also making continuous progress and developed the ERE series.

For Elang ERE series, the E represents “ Elang, Efficiency & Economic”. this series is designed for the customer who didn’t have much budget. “ Quality First, Integrity-based” is the everlasting operation tenet of the Elang Group. It is also applied in the series, compared to the very cheap compressors which produced on Guangdong, Jiangxi and Shandong province, Elang ERE series still use high quality spare parts and more durable chassis and canopy to support longer service life.

|

Solid Reasonable Structure Design ■ More thicker canopy and more solid chassis are adopted, production costs higher but the service life can be extended and ensured. ■ Reasonable internal structure layout and stable operation, with durable and reliable parts, and the daily maintenance cost is lower. |

|

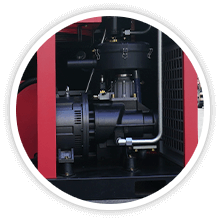

Air End ■ The air end adopts a new generation of profile with integrated shaft structure, compact structure, stable operation and high energy efficiency. |

|

High Quality Fan Assembly ■ Higher quality fan and fan motor is adopted, lower noise and vibration, it can be used for more different working occasions. |

|

Energy Efficient Cooler ■The cooler adopts super large heat exchange area design to improve the cooling efficiency, effectively prevent the compressor from high temperature, and prolong the service life of the compressor. |

|

Intelligent PLC ■ Touch screen with multiple languages for choose. ■ Full protection functions for motor and compressors. ■ Remote control with RS485 and IOT function available. |

|

Dust Screen ■ Stop most of the dust, moisture, and etc, to increase the service life of air end, air filter and oil filter, protection the system. |

|

Optimum Designed Oil Gas Tank ■ The oil-gas tank with super large capacity ensures lower system pressure difference. ■ The oil separator element with better quality is equipped with advanced three-time oil-gas separation effect, and the oil content is below 3ppm to ensure the high quality of compressed air. |

|

High Efficiency Inverter and PM Motor ■ For VSD compressor, well-known frequency inverter brand is adopted with higher stability and reliability. ■ Small starting impact to avoid overload starting. Energy efficiency can be achieved by adjusting the frequency. ■ Professional customized high-efficiency permanent magnet motor (PM motor), to ensure better energy saving efficiency. |

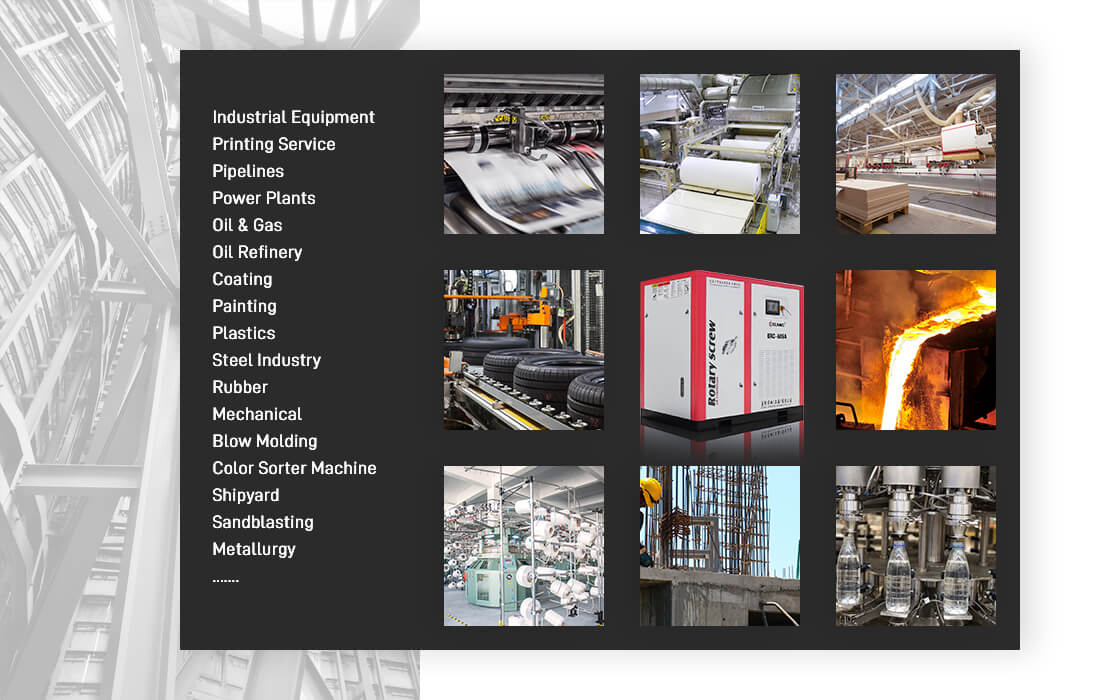

Applications:

| Model | Working Pressure | Air Delivery | Motor Power |

Dimension (mm) |

Weight | ||||||

| PSIG | BAR | CFM | m3/min | kW | HP | L | W | H | KG | ||

| ERE-10SA | 100 | 7 | 38.3 | 1.1 | 7.5 | 10 | 700 | 550 | 800 | 110 | |

| 116 | 8 | 35.3 | 1 | ||||||||

| 145 | 10 | 30 | 0.85 | ||||||||

| 180 | 12.5 | 24.7 | 0.7 | ||||||||

| ERE-20SA | 100 | 7 | 84.7 | 2.4 | 15 | 20 | 1010 | 600 | 1030 | 212 | |

| 116 | 8 | 77.8 | 2.2 | ||||||||

| 145 | 10 | 74.2 | 2.1 | ||||||||

| 180 | 12.5 | 63.6 | 1.8 | ||||||||

| ERE-30SA | 100 | 7 | 134.2 | 3.8 | 22 | 30 | 1100 | 850 | 1130 | 301 | |

| 116 | 8 | 127.1 | 3.6 | ||||||||

| 145 | 10 | 113 | 3.2 | ||||||||

| 180 | 12.5 | 88.3 | 2.8 | ||||||||

| ERE-50SA | 100 | 7 | 233 | 6.6 | 37 | 50 | 1300 | 1000 | 1260 | 442 | |

| 116 | 8 | 218.9 | 6.2 | ||||||||

| 145 | 10 | 201.3 | 5.7 | ||||||||

| 180 | 12.5 | 162.4 | 4.6 | ||||||||

Leave Us Your Feedback

Related Product

PM VSD Screw Air Compressor

Working pressure: 7 ~ 12.5 bar 100 ~ 181 psig

Air delivery: 0.72 ~ 102.0 m3/min 25.4 ~ 3601.6 cfm

Working powe...

More >

Frequency Conversion Screw Air Compressor

Working pressure: 7 ~ 13 bar 100 ~ 181 psig

Air delivery: 1.0 ~ 102.0 m3/min 35.3 ~ 3601.6 cfm

Working power: 22 ~ 5...

More >