Advantages:

-

PM motor has 2~ to 7% higher working efficiency than three-phase asynchronous motor. No matter in underloading or overloading conditions, PM compressors keep high working efficiency while three-phase asynchronous motor will have fluctuant efficiency according to the loading conditions. Therefore, compressors with PM motor will save 8% to 30% energy than those with three-phase asynchronous motor.Specialized PM motor has power factor large than 0.95, even close to 1 in some models. Moreover, PM compressors are installed with frequency converter to realize variable frequency starting and decrease the impact to compressor unit and power grid during starting, so as to save operation costs.

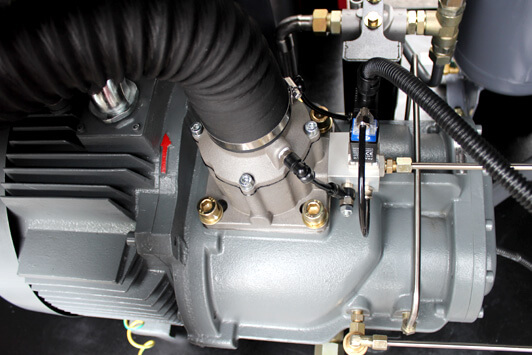

1.servo air compressor is a modern new technology air compressor with novel and beautiful appearance.

2.Internally efficient, energy saving!

3.Small machine size, Silent ,durable and run smoothly!

4.Save many troubles of regular maintenance and replacement.